Walton Motorsport Honda K20/K24 RWD Conversion Exhaust Manifold

Walton Motorsport Honda K20/K24 RWD Conversion Exhaust Manifold

Couldn't load pickup availability

Walton Motorsport Honda K20/K24 Exhaust Manifold

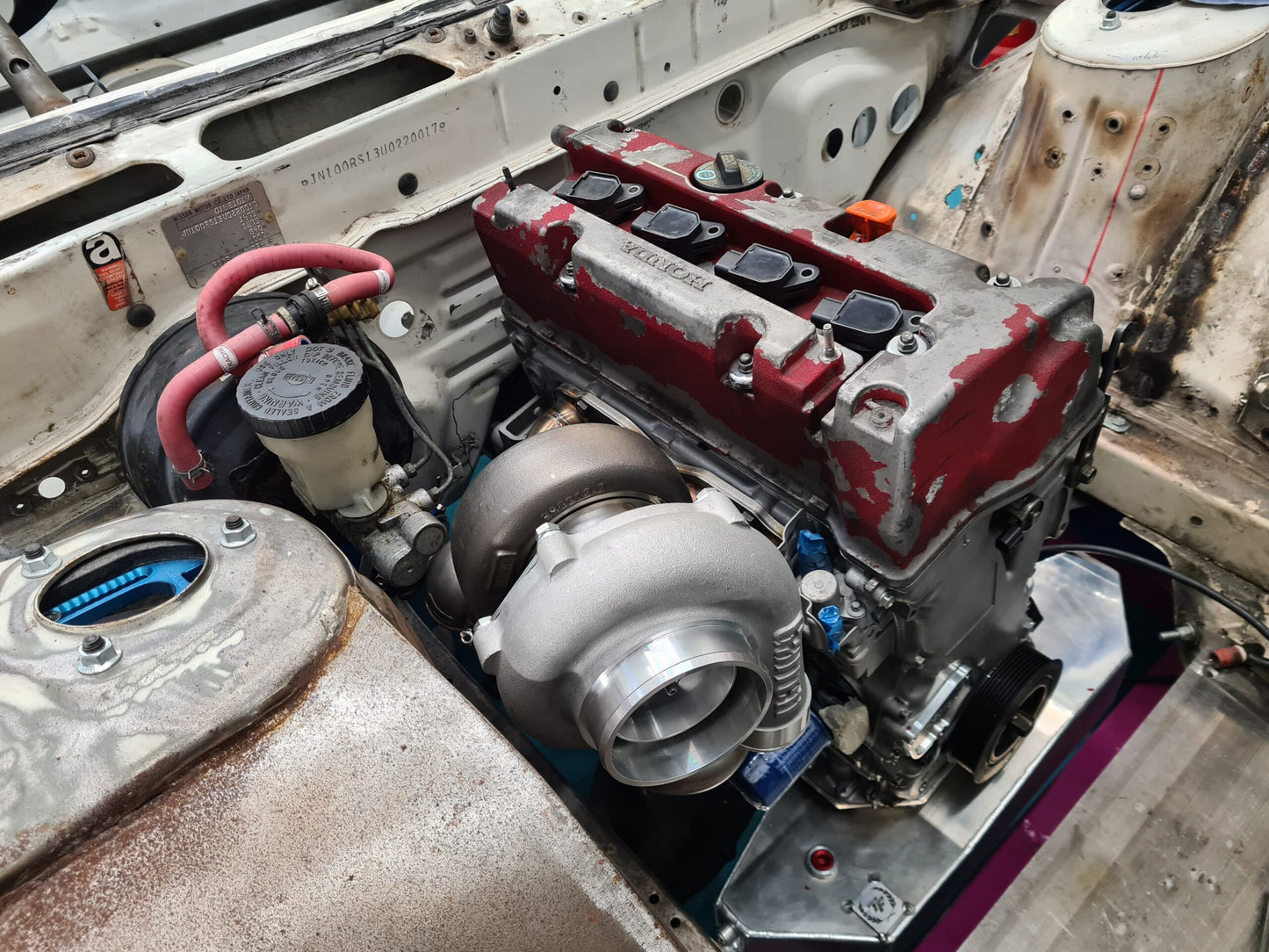

The Honda K20 and K24 Engine is rapidly gaining popularity, especially in RWD applications. Suited to a Garrett G Series Turbo (G25, G30, or G35) and compatible with RWD Conversions such as Nissan S-Bodys it’s the perfect solution to start boosting your Honda K Series.

There’s no shortage of Honda K20 and K24 exhaust manifolds available. The construction methods we use set our product apart from our rivals.

HONDA K20 AND K24 EXHAUST MANIFOLD CONSTRUCTION

Material Selection

- First and foremost not all 304 Stainless steel is created equal. We carefully select the exact specification of the tube that we use. The use of poor-quality tubes can compromise the whole design. For Instance, exhaust manifolds experience repeated high-temperature cycles. In these situations, we have seen poor tubing split along the seam.

- We design the head flanges in-house. However, we outsource the precision Fiber Laser Cutting. The use of more modern Fiber Laser cutting allows for increased accuracy over traditional laser cutting

Processes

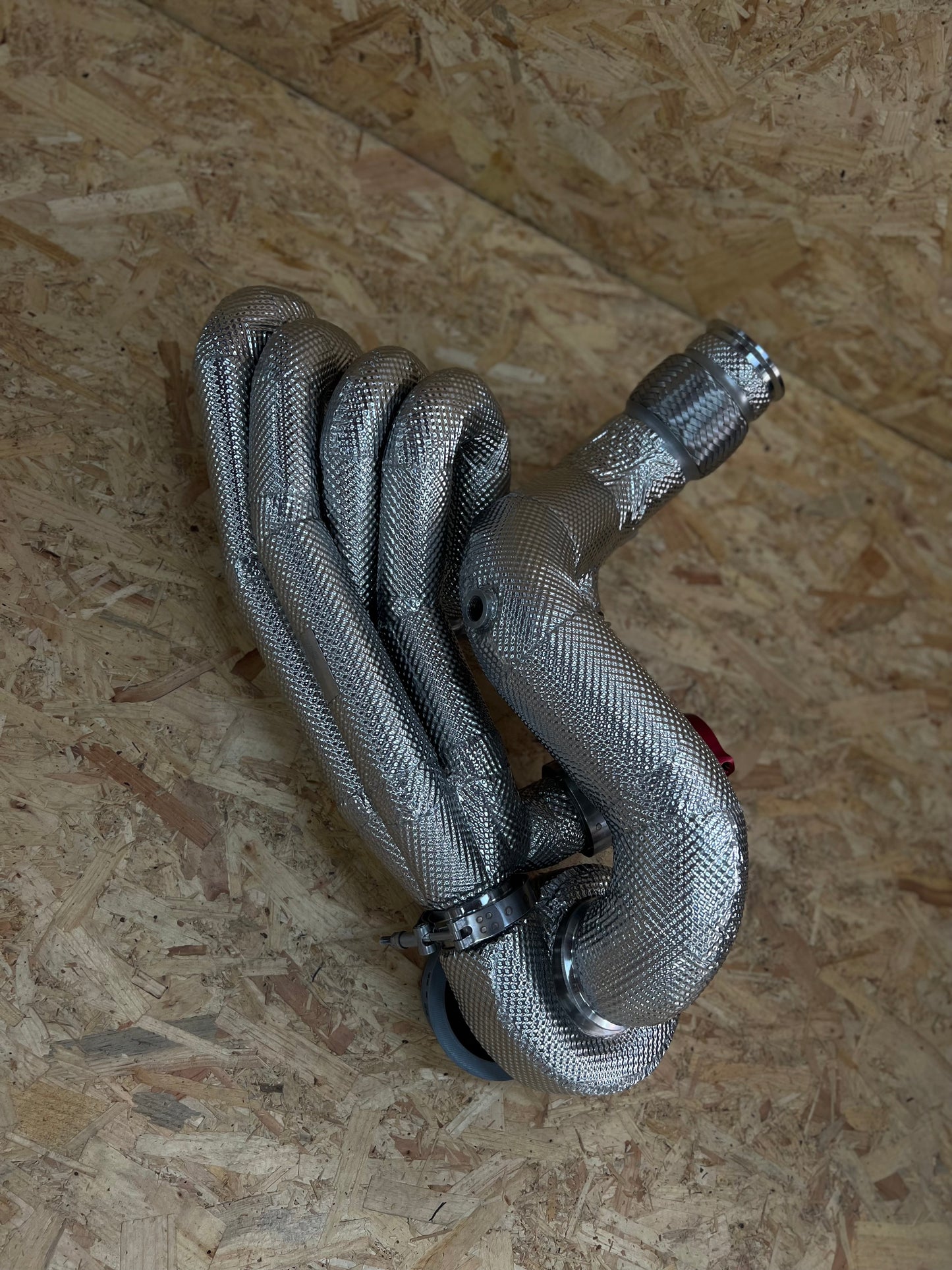

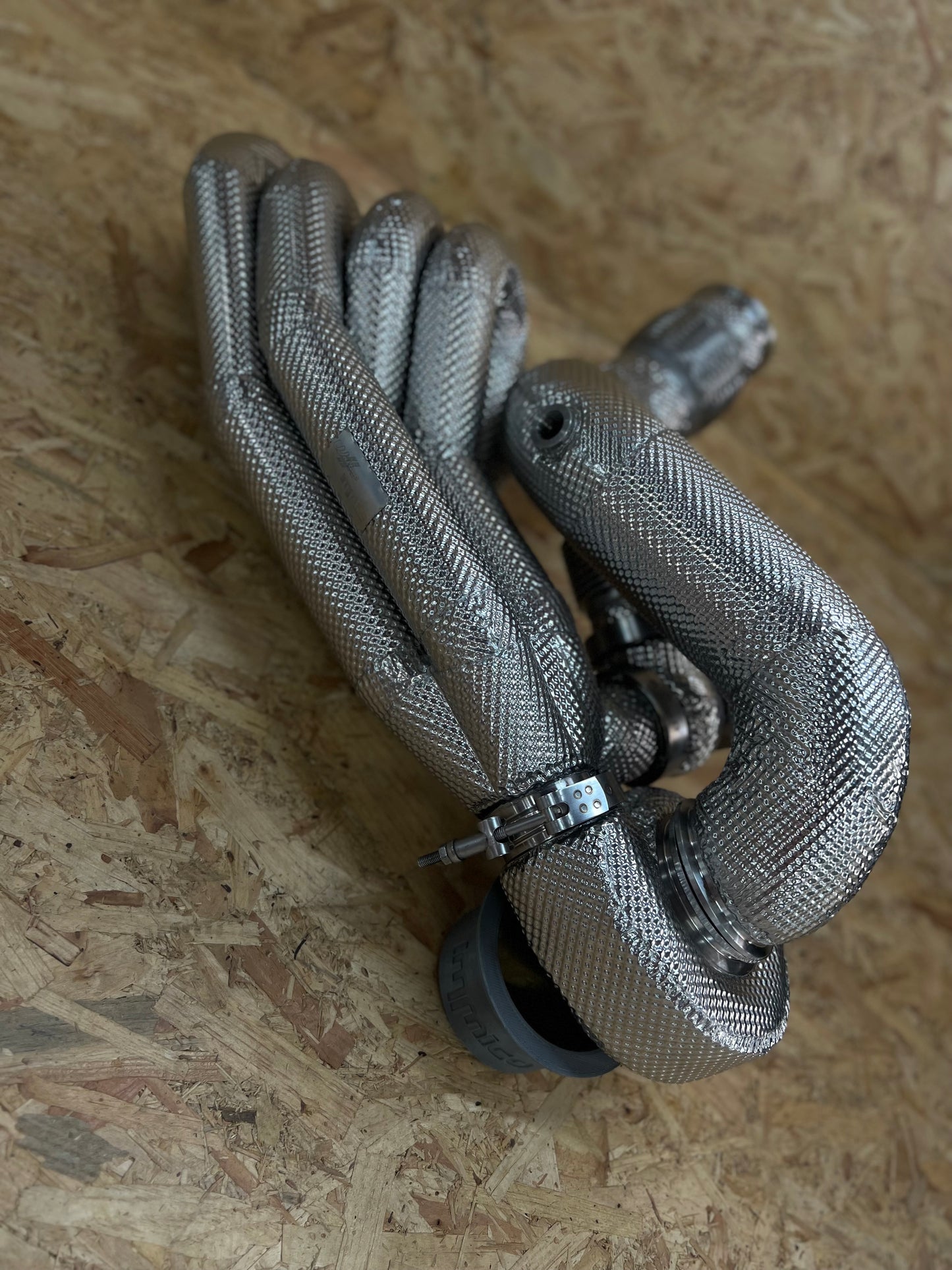

- Where the manifold meets the exhaust ports, Walton Motorsport’s process is to push the tubing through the head flange and TIG weld each side. This process is followed by a selection of finishing tools. We do this to create a smooth port for the gasses to freely flow through. Consequently, this process greatly increases the durability of the manifold. Rather than using the traditional method of welding the tube to the face of the flange. Moreover, our method is where we also face the problem of an oval port needing to transition smoothly to a round tube. The stubs process, in short, helps increase power through the improved flow.

- The collector we use is a custom billet merge collector. We proudly designed this collector in-house to exceed the performance of our previous market-leading hand-fabricated version. The freedom of design we have utilizing the complex 5-axis mill production process really allows us to be a step above the competition by allowing precision boost control on our unique wastegate ports. The machining process over traditional fabrication ensures that there is no danger of small fragments breaking off at high temperatures. These fragments will then make their way through your expensive turbo. We don’t need to tell you how bad that can be. And did we mention its machined in the UK?

LIFETIME WARRANTY

Bombproof? We haven’t found out yet. Walton Motorsport has designed the manifolds to put up with some serious abuse though. We offer a lifetime warranty on our products as many do. However, we put a huge emphasis on the strength and durability of our products to stop them from failing. The biggest inconvenience when it comes to a failed manifold (providing none of it ends up inside your turbo or engine) is removing it for repair. By eliminating the failure in the first place, we can honestly say it would be extremely unlikely to experience a failure of our products. Consequently, We wouldn’t sleep well at night if our product failed and cost you a result.

HONDA K20 AND K24 EXHAUST MANIFOLD FEATURES

- Carefully selected 304 Stainless steel tube. Working to eliminate the risk of material failure.

- Fully Purged welded. Subsequently improving gas flow leads to increases in power and lowered response times.

- Our unique in-house designed and UK-manufactured billet collector. Resulting in high strength, durability, and turbo lifespan.

- Multi-primary pipe wastegate port design developed with leading engine tuners to allow high control and remove boost creep.

- Fully Smoothed Head Ports designed to optimize gas flow. As a result, providing an increase in power and lowered response times.

- Optimised for use with Turbosmart GenV ProGate 50mm wastegates.

FITMENT NOTES

- Does not fit MX5 Chassis due to high chassis legs

- Compatible with Nissan S-Body

- Compatible with GT86

*Please note that although this item is shown as 'in stock' these manifolds are made to order - lead time is typically 1-2 weeks. However we do carry stock of certain manifolds.

Why Not Add Some Heat Protection

Immico Thermo Immission Control

Fully welded solution using high quality thermal matting with bespoke fabricated dimpled foil casing. This solution provides significant performance benefits with a minimum surface temperature reduction recorded at 75%. With a range of thicknesses available to suit different applications, this can raise to over 90%.

With advanced welding techniques and high quality dimpled casing this increases the life cycle of the insulation making it a fit and forget product with high performance.

*Please allow for an additional 2-3 weeks for Immico Thermo Immission Control

Share